Community Give Back

Join us in supporting amazing local non-profits. Every Monday and Wednesday, $1 from every adult beverage will be donated to the charity of the day.

Our Beers

We’re not brewing just for beer judges.* We’re making creative, delicious, drinkable beers for everyone. We’re for any time you get together. It’s beer for anywhere. See what’s brewing.

*But beer judges do like us too…

View our Year Round, Seasonal, and even our Brewery Tap Lists brews.

Visit Us

Downers Grove

Brewery + Taproom

Where it all began! Rotating tap list of 12 beers, free parking, private event spaces.

Oak Brook

Brewery + Kitchen

Full restaurant with 16 taps located just east of Oak Brook Mall on 22nd and Spring Rd.

St Charles

Brewery + Kitchen

Our second location is nestled along the Fox River in the heart of downtown St. Charles.

Not Your Typical Brewers

Alter Brewing was born from a lot of different backgrounds. What unified us was a love of how great beer could bring people together.

That’s why we do what we do. We just want to be on your table (or have you at ours).

Host Your Event At Alter

Our Brewery has two unique spaces for parties of nearly any size. You get great beer, great food, great service, and a whole lot more. From weddings to corporate events to just wanting to celebrate being friends and family, we’re where people get together.

Brew Blog’s Latest

March Mashness

Attention all beer and bball lovers! We’re pumped to introduce our first Alter Brewing March Mashness bracket. We have been […]

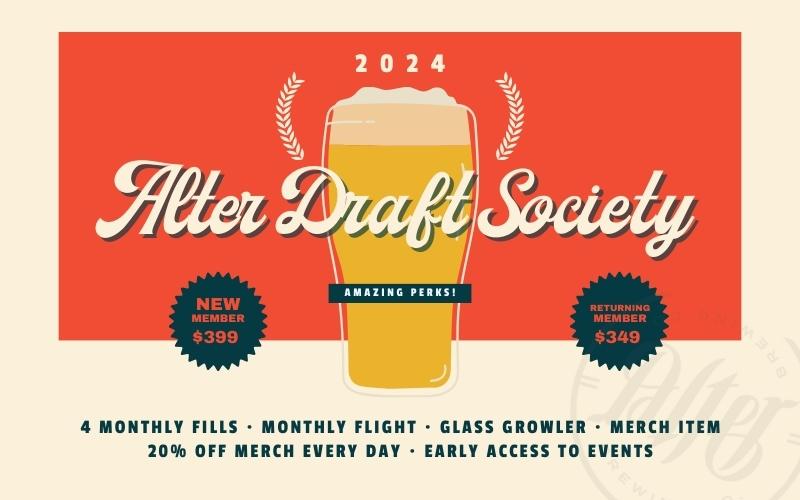

Alter Draft Society

The growler club is back and has a killer new name. Welcome to the Alter Draft Society! Our annual club […]